References Medical

Application of the plasma polishing process

Medical technology

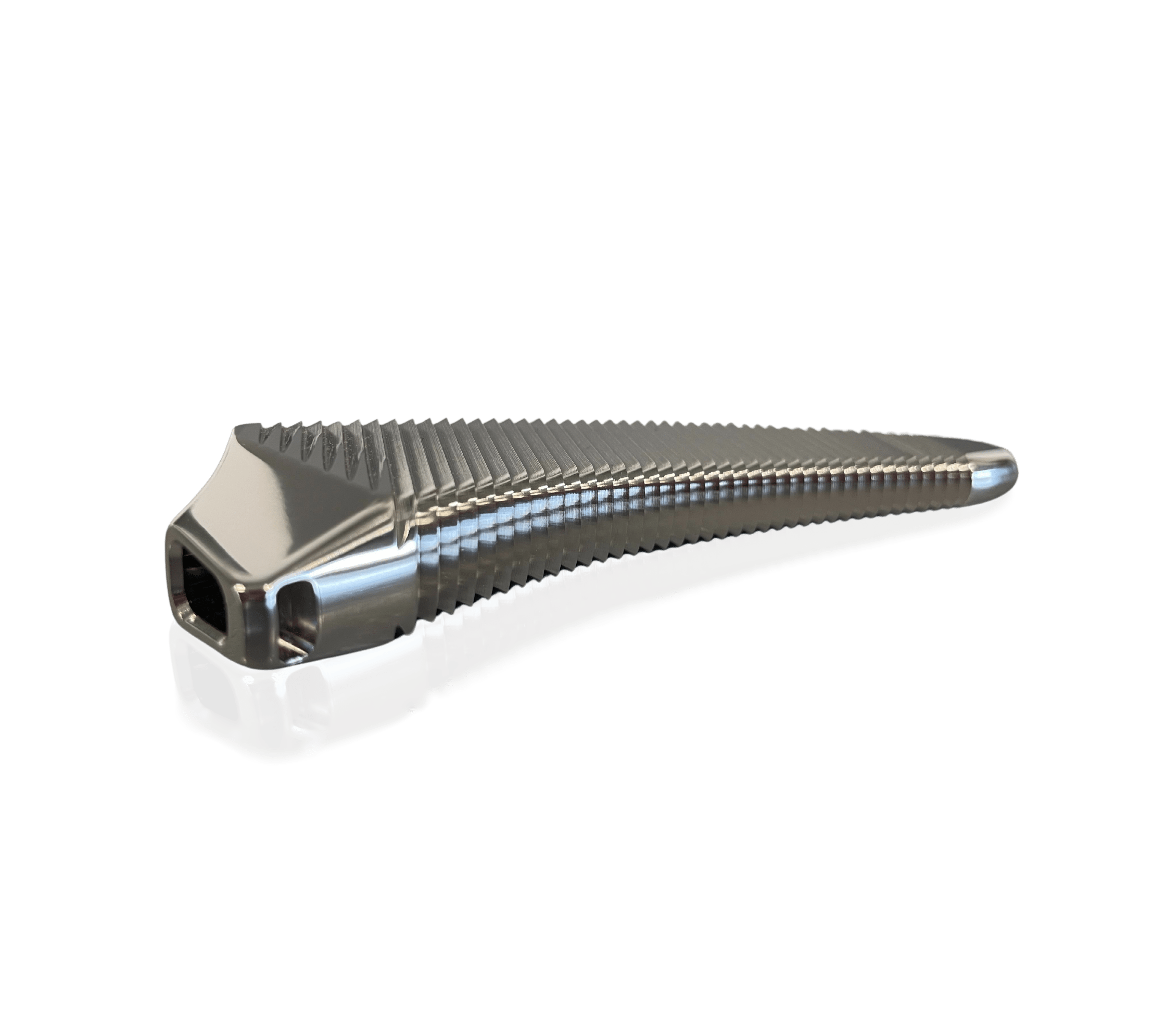

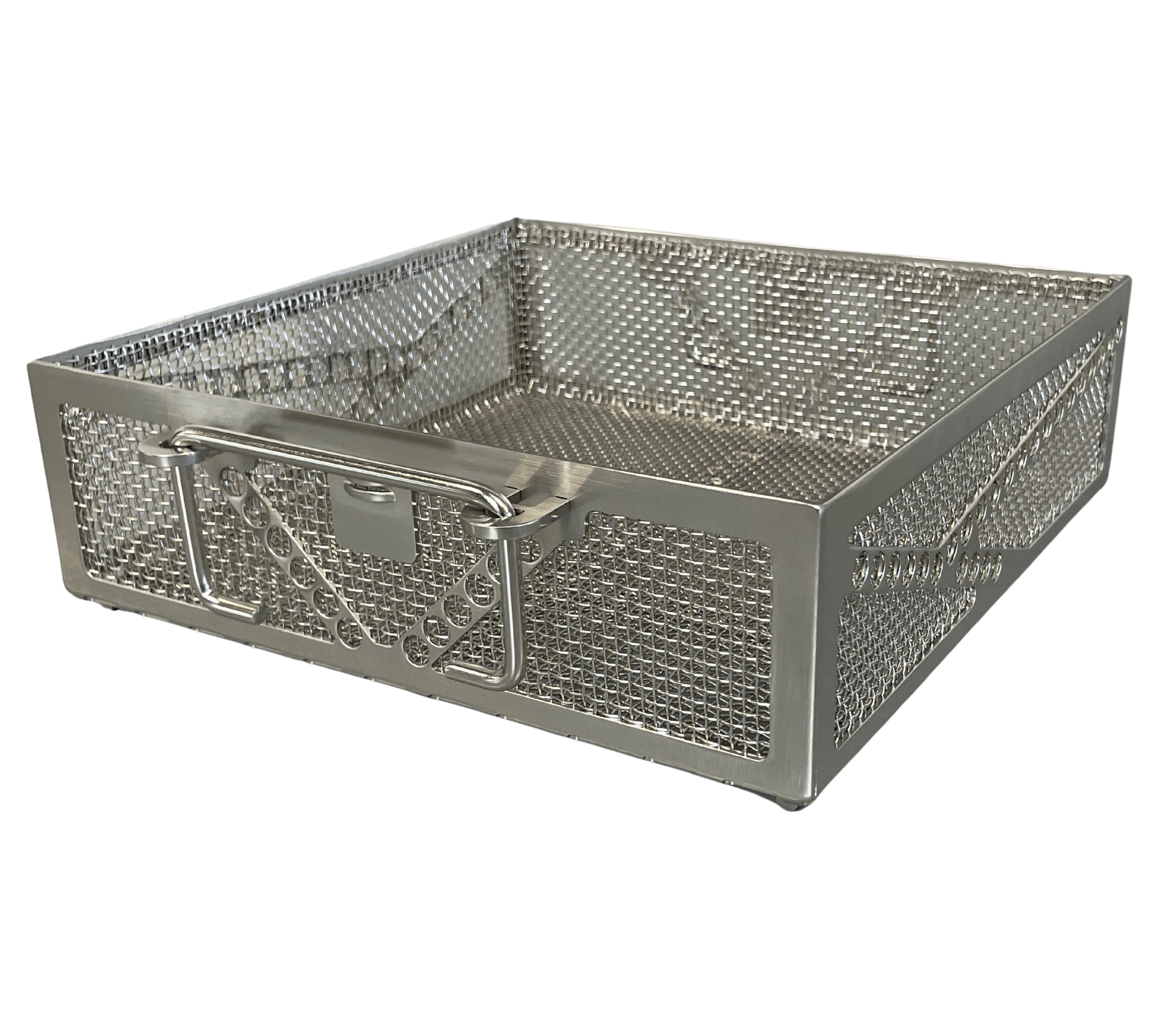

The plasma polishing process is very well suited to processing the surfaces of instruments and implants made of stainless steel, titanium and titanium alloys. The low removal rates ensure absolute dimensional accuracy of fits and small dimensional tolerances. A time-controlled polishing process allows burrs on cutting edges to be gently removed without negatively affecting the cutting quality. Artificially matt-finished surfaces are given a uniform and matt-finished glossy burr. The plasma-polished surfaces show no cytotoxic effects and are also protected against corrosion by the passivation effects of the process.

New process developments will enable partial polishing of implants in the future. This will allow specific areas of a workpiece to be processed in a targeted manner. This has the advantage that several surface properties can be found on one workpiece.