About us

plasotec GmbH

An innovative surface technology company.

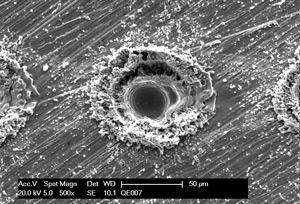

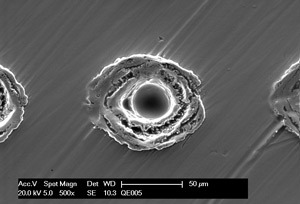

Polishing, deburring, cleaning of metallic workpieces.

plasotec GmbH is your competent partner with over 15 years of expertise in the processing of metallic surfaces using plasma electrolytic processes. Our company stands for innovative solutions and the highest quality in surface technology. With state-of-the-art technology and comprehensive know-how, we offer customized services for a wide range of industries, including medical technology, food technology, the pharmaceutical industry, the semiconductor industry and conventional mechanical engineering.

Our specialized plasma electrolytic processes ensure outstanding surface quality with high wear resistance, corrosion protection and aesthetic improvement. As a leading supplier, we rely on sustainable and environmentally friendly technologies that simultaneously reduce costs and increase energy efficiency.

In contrast to conventional electropolishing, the plasma polishing process works with easy-to-handle and environmentally friendly electrolytes. Due to the cleaning and degreasing effect of the superimposed plasma, no pre-treatment of the parts is required. In addition to polishing, the plasma polishing process is also suitable for decoating surfaces.

You can rely on plasotec GmbH’s many years of experience to give your metallic surfaces an optimum finish. Contact us today and benefit from our innovative solutions and first-class service.

Translated with DeepL.com (free version)

Advantages

The innovative plasma polishing process offers a whole range of advantages that make it suitable for use in a wide variety of applications. The properties of plasma polishing make this technology particularly suitable as a problem solver for polishing, cleaning and deburring metallic surfaces.

- levelling of micro-roughness (< 0,01 µm)

- minimal material removal

- processing of any contours is possible

- a previously unattainable degree of gloss can be achieved

- no pre-treatment or special cleaning of the workpieces is necessary

- use of environmentally friendly electrolytes

- no use of environmentally harmful substances and highly concentrated acids

- increased corrosion resistance of plasma-polished surfaces

- minimal thermal and mechanical stress on the surface (t < 100°C)

- no cytotoxic effects are to be expected on plasma-polished surfaces